Work Packages

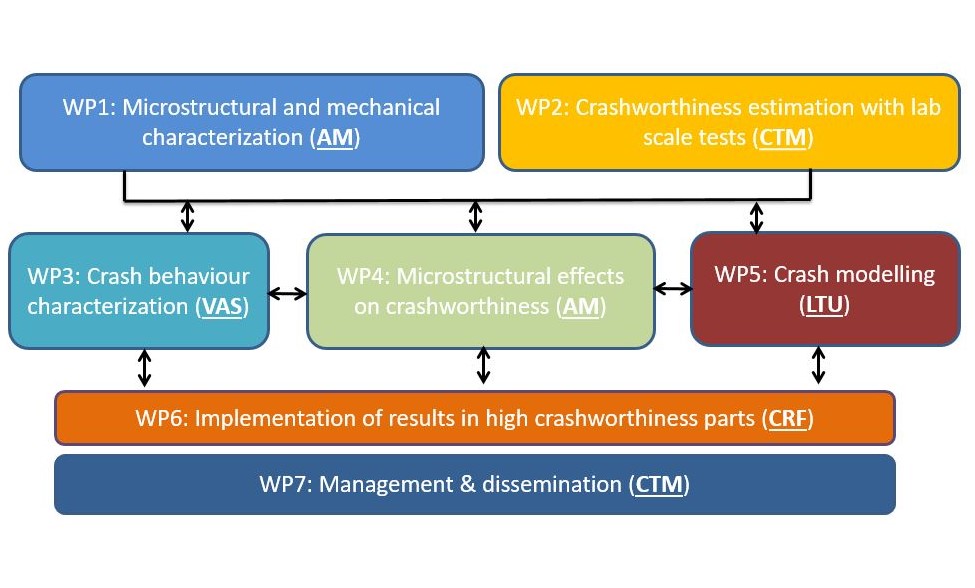

Crash&Tough methodology is divided into 7 work packages (WP). It combines experimental tests at laboratory scale (WP1, WP2 and WP3) and crash tests in demonstrators (WP6) with detailed microstructural characterizations (WP4), FE models (WP5) and innovative analysis techniques for crack nucleation and propagation path inspection (WP4). Demonstrators will be tested (physical and virtual) in WP6 to validate the developed FE models. A brief description of the WPs is given below:

WP1. Microstructural and mechanical characterization. The aim of this WP is to select the steel grades to be studied, prepare the blanks and perform the microstructural and mechanical characterizations of the selected TRIP-assisted steels with different retained austenite contents.

WP2. Crashworthiness estimation with lab scale tests. In this WP, the crash behaviour of the AHSS sheets will be estimated by means of laboratory scale tests. V-bending tests will be performed to obtain the bending angle at fracture and fracture strain in plane strain tension. Fracture toughness of the AHSS sheets will be characterized by means of EWF tests. From the tests the energy released for crack nucleation and the overall energy to fracture will be assessed. Results obtained in this WP will be implemented in crash modelling in WP5.6 steel grades will be selected to characterize their crash behaviour on WP3.

WP3. Crash behaviour characterization. Crash behaviour of the different AHSS will be characterized by means of axial tests and bending tests. Tensile tests and EWF tests at different strain rates will be performed to evaluate the influence of strain rate on tensile properties and fracture toughness. Additionally, medium strain rate tests at different stress-states will be performed, aimed to fully characterize the influence of strain rate and stress-state on material behaviour. The relation between crash behaviour and fracture resistance characterizations (WP1, WP2) will be investigated. 4 steels will be selected according to results for the design of 1 high crashworthiness part at WP6. Results will be used as an input for crash modelling in WP5.

WP4. Microstructural effects on crashworthiness. This WP aims to understand the microstructural effects (mainly RA contribution and matrix properties) on crack propagation resistance. For this purpose, a detailed microstructural characterization will be carried out. Moreover, fractographic analysis and EBSD investigations to follow the RA transformation during crack propagation will be performed. Crack nucleation and propagation mechanisms will be assessed by in-situ crack path propagation observations by SEM-EBSD.

WP5. Crash modelling. Crash simulations will be addressed by identifying and implementing both energy and strain-based failure criteria. A damage evolution model based on fracture mechanics will be obtained to predict the whole fracture energy during crack propagation. Two approaches to predict the initiation of damage will be applied: the failure strain determined by bending tests (WP2) and the failure strain determined by strain-based failure criteria (WP3), taking high strain rates and stress state into account.

WP6. Implementation of results in high crashworthiness parts. The objective is to implement the results obtained in the previous WP’s in a demonstrator chosen from an automotive component. It will be here manufactured using 4 AHSS grades selected in WP3. The demonstrator will be experimentally and virtually tested. The reliability of the methodology will be experimental assessed. The weak points will be detected and improved in order to establish an affordable alternative for real crash tests.

WP7. Management & dissemination. Addresses coordination, dissemination, IPR and exploitation issues.